HIGHWAYS ROAD USING 100% RECYCLED MATERIALS

Research shows that approximately 8 million tons of plastic are thrown into the ocean every year, and 55% of all plastic waste is burned. Therefore, by using this route, many advantages are created.

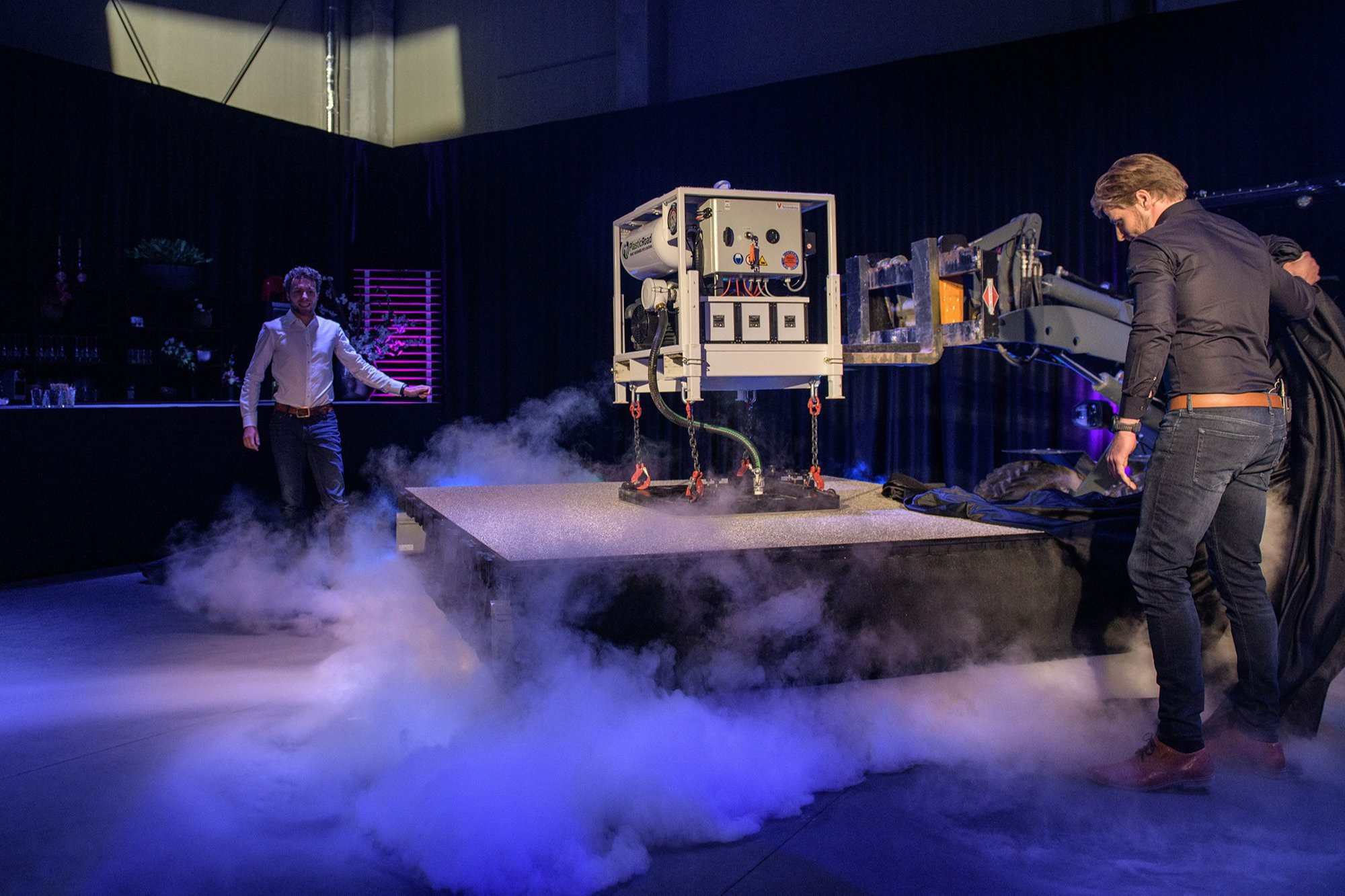

The Dutch company PlasticRoad has developed a new type of road material, CCL200 and CCL300, which is made from 100% recycled plastic waste. The project was implemented in 2018 and in September 2018 in Zwolle, the Netherlands, 1,000 kg of waste equivalent to 218,000 plastic cups were used to build a 30-meter 2-lane bike path, which reduced carbon dioxide (CO₂) emissions by 50-70% compared to conventional paved roads. out.

Advantage

For materials:

- Resistant to extreme weather conditions

- Durability is long

- Low carbon dioxide (CO₂) emissions

- Light weight

As for the workflow:

- Due to the ease of installation, it is done 3 times faster than with hard paving;

- Low shipping costs due to light weight;

- Can be used immediately after completion of the construction process;

- Drainage facilities are not required;

- The electrical network was decided on its own

Disadvantages

- Because it is made of pure plastic, it melts at extremely high temperatures and breaks down into microplastic particles that can enter the soil and waterways.

- Do not use all types of plastic.

- If this technology is further researched and developed so that it can be used in the construction of highways and highways, it is possible to make great progress in the environment and the highway industry.

Source: https://plasticroad.com/en/projects/